The first ever 3D printer designed to be used in space will shortly arrive at the International Space Station (ISS) where it will be tested on board the Columbus module.

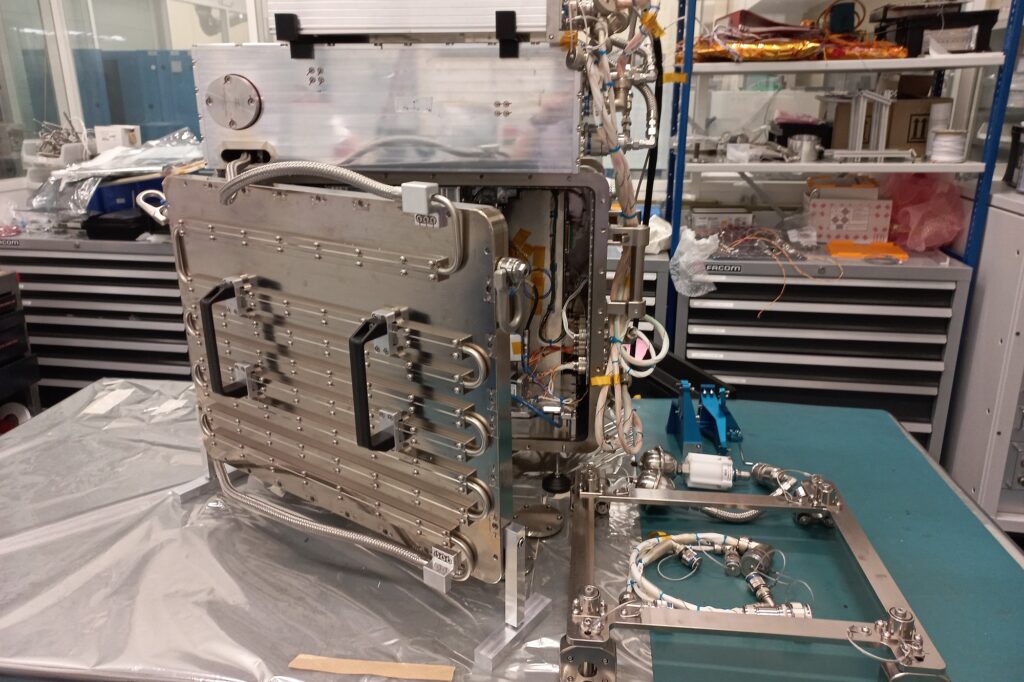

The 3D metal printer was created and designed by Airbus for the European Space Agency (ESA), with hopes that the washing-machine-sized contraption will aid future missions to Mars and the Moon.

There are currently several plastic 3D printers on board the ISS which are frequently used by astronauts. However, the tools to produce metal objects in this way have not been available until now.

Astronauts based on the ISS can often wait months for metal replacements to be delivered from Earth, so there are hopes that the metal 3D printer may be a game changer.

Gwenaëlle Aridon, Airbus Space Assembly lead engineer, said: “The metal 3D printer will bring new on-orbit manufacturing capabilities, including the possibility to produce load-bearing structural parts that are more resilient than a plastic equivalent. Astronauts will be able to directly manufacture tools such as wrenches or mounting interfaces that could connect several parts together. The flexibility and rapid availability of 3D printing will greatly improve astronauts’ autonomy.”

Printing metal in space poses a raft of unique problems and Airbus will be gathering data about how the new machine performs.

The average 3D printer normally requires a 10m² laboratory as a minimum, so Airbus engineers have had to significantly reduce the size.

Another consideration involved ensuring that the space station is protected from the laser and the heat generated by the metal 3D printer.

Although the printer sits in a safe-like box, the melting point of metal alloys compatible with this process can be far over 1,200°C degrees, compared to around 200°C degrees for plastic.

“Gravity management is also key, which is why we chose wire-based printing technology. The wire is independent of gravity unlike the powder-based system, which always has to fall to the ground,” Sébastien Girault, metal 3D printer System Engineer at Airbus, said.

Whether from plastic or metal, fumes are emitted that must be passed through filters and captured inside the machine so that they do not contaminate the air within the ISS.

An exact replica of the 3D printer on Earth will mirror some of the work completed by the space-based machine.

Four sample parts made by the 3D printer on the ISS will be sent back to Airbus for comparison against those produced by the Earth-based machine.

The metal 3D printer was developed by a consortium comprising Airbus Defense and Space, AddUp, Cranfield University and Highftech Engineering, under a program run and funded by the European Space Agency (ESA).

The metal 3D printer took off for the ISS aboard the SpaceX Falcon 9 rocket on January 20, 2024.