As Boeing looks to toughen its quality control checks in the wake of the Alaska Airline 737 MAX 9 plug door blowout, the CEO of Boeing Commercial Airplanes, Stan Deal, has written to staff outlining steps that will be taken to restore confidence with customers and regulators.

In a message sent on January 15, 2024, Deal told staff that Boeing had been working with the five affected airlines to inspect their 737-9 fleets and ensure “plug doors are installed per specification”.

On January 12, 2024, the Federal Administration Agency (FAA), announced that it had instructed Boeing to provide additional data from 40 plug door inspections on grounded MAX 9 aircraft.

The FAA said that only when enough data is provided will it approve Boeing’s inspection and maintenance instructions that will need to be carried out on every aircraft before it is returned to service.

In his message to employees Deal said that Flight AS1282 showed that Boeing “is not where we need to be” and immediate action is needed to “bolster” quality assurance.

The new steps set out in the internal memo included allowing for 737 MAX operators to come into Boeing and Spirit AeroSystems factories for additional oversight inspections.

Deal also added that Boeing will carry out inspections throughout the build process at Boeing and Spirit to provide “one more layer of scrutiny on top of the thousands of inspections performed today across each 737 plane”.

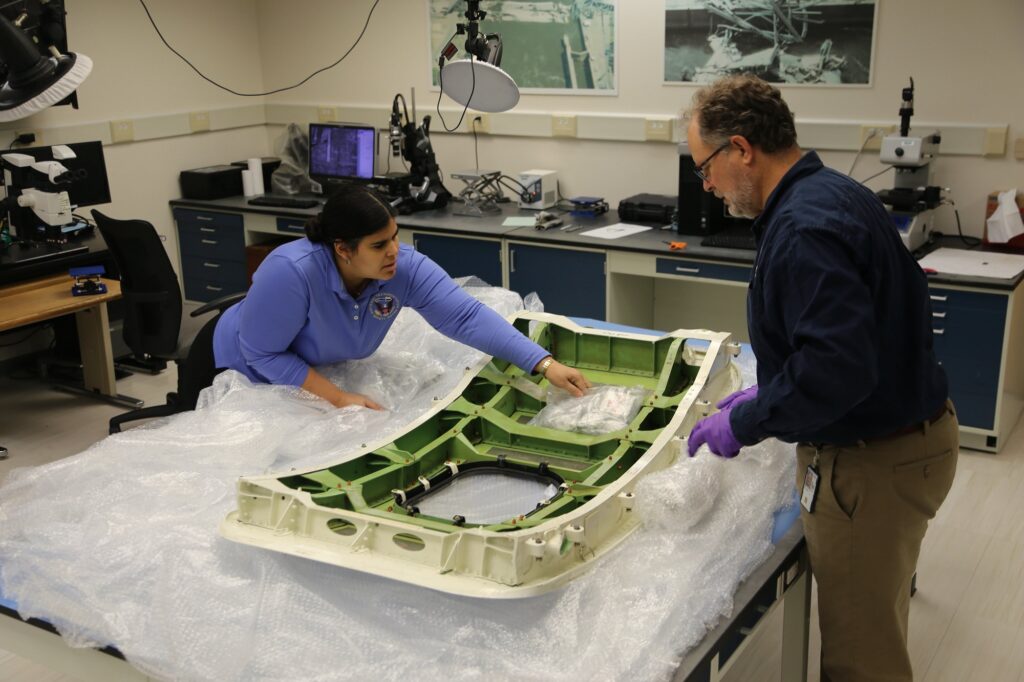

Deal confirmed that a team from Boeing had been sent to Spirit to inspect and look at how the mid-exit door plugs are being installed before the fuselage is sent to the planemaker.

Boeing is also checking more than 50 other points during Spirit’s manufacturing timeline and “assessing their build plans against engineering specifications”.

Finally Deal said that Boeing will bring in an “outside party” to review its Quality Management System and suggest improvements.

What the FAA says

Boeing’s quality assurance plan is separate to the one that the FAA set out in a strongly worded statement on January 12, 2024, in which it announced, “new and significant actions to immediately increase its oversight of Boeing production and manufacturing”.

The FAA statement came just a day after it formally notified Boeing that it had launched an investigation into the company as a result of the Alaska Airlines plug door blowout.

The FAA said that it would conduct an audit involving the 737-9 MAX production line and its suppliers to “evaluate Boeing’s compliance with its approved quality procedures”.

The agency also said it would assess “safety risks around delegated authority and quality oversight” and explore these functions being carried out by independent third parties in the future.

“It is time to re-examine the delegation of authority and assess any associated safety risks,” FAA Administrator Mike Whitaker said. “The grounding of the 737-9 and the multiple production-related issues identified in recent years require us to look at every option to reduce risk. The FAA is exploring the use of an independent third party to oversee Boeing’s inspections and its quality system.”

We are working to make sure nothing like this happens again. Our only concern is the safety of American travelers and the Boeing 737-9 MAX will not return to the skies until we are entirely satisfied it is safe. https://t.co/KueycCGYBQ

— FAA Mike Whitaker (@FAA_Mike) January 13, 2024

On January 13, 2024, Alaska Airlines announced the commencement of its own quality control audit for up to 20 of its Boeing 737-9 MAX aircraft, aligning with the requirements set by the FAA.

The FAA grounded a total of 171 Boeing 737 MAX 9s, including 65 Alaska Airlines jets, after a plug door separated from an Alaska Airlines aircraft at just over 16,000 feet in the air.

The incident occurred on January 5, 2024, shortly after takeoff from Portland International Airport (PDX) while flying to Ontario International Airport (ONT) in California.