The US National Transportation Safety Board (NTSB) has published its preliminary investigation report into the Alaska Airlines Boeing 737 MAX 9 plug door blowout incident.

The 19-page document details how events unfolded on January 5, 2024, but perhaps more critically the report focuses on what happened before the 737-9 left Boeing’s Renton facility for delivery to Alaska Airlines.

The preliminary report confirmed that four key bolts designed to hold the plug door in place were missing.

“Four bolts that prevent upward movement of the mid exit door plug were missing before the mid exit plug moved upward off the stop pads,” the NTSB said.

The NTSB drew this conclusion partly because investigators “observed damage patterns and absence of contact damage or deformation” around holes associated with the four bolts which suggested that they were not in place during the incident.

The @NTSB has released its preliminary report on the #AS1282 #737MAX-9 door plug accident. Highlights:

— Jason Rabinowitz (@AirlineFlyer) February 6, 2024

• Indications that…"four bolts that prevent upward movement of the MED plug were missing before the MED plug moved upward off the stop pads." pic.twitter.com/4G90dN8Eg0

This chimed with an earlier report from a person purporting to be a whistleblower at Boeing who wrote that the bolts were “not installed when Boeing delivered the airplane”.

With the evidence suggesting that the four bolts were not present when the plug door separated from the Alaska 737-9, the logical question to ask is why they were not there.

The plug door itself was manufactured by Spirit AeroSystems Malaysia on March 24, 2023, and was received at Spirit AeroSystems Wichita on May 10, 2023.

According to records, the Alaska fuselage with the door plug installed arrived at Boeing’s Renton facility by rail on August 31, 2023.

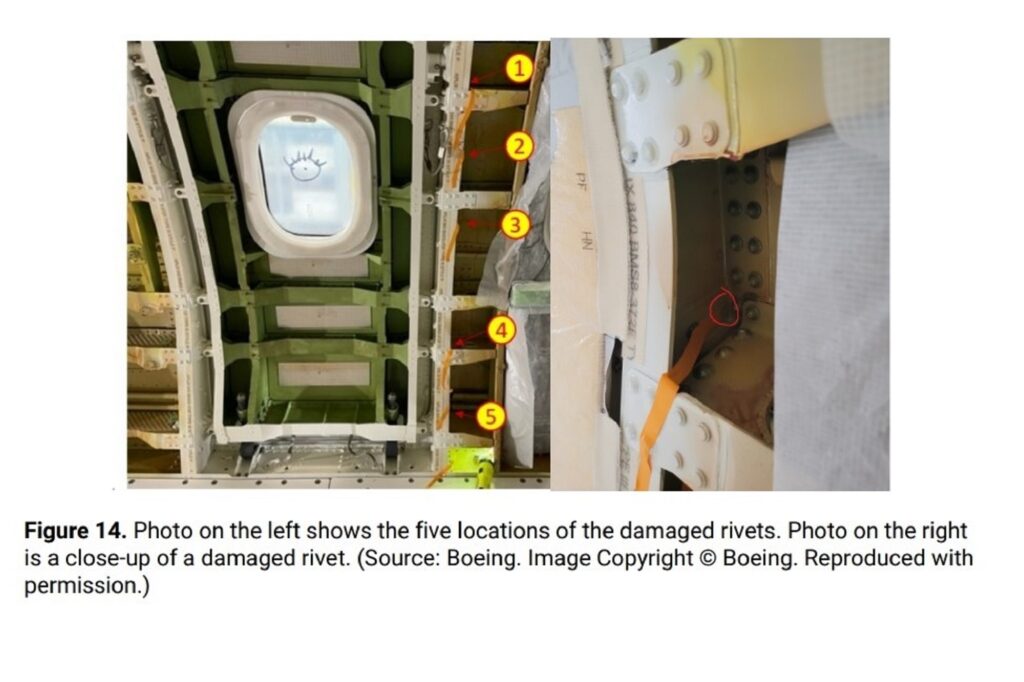

On September 1, 2023, a Non-Conformance Record (NCR) was created noting “five damaged rivets on the edge frame forward of the left plug”.

The NTSB said in its report that to fix the five rivets the plug door was opened, and the four bolts were removed.

Records obtained by the NTSB show that the rivets were replaced and fixed on September 19, 2023, by Spirit AeroSystems workers.

Later that same day at 6.39 pm an image of the plug door closed was shared by a Boeing employee to a colleague via text while they were discussing interior restoration following the repair work.

According to the NTSB the photo was taken before interior restoration and after the rivet rework was completed.

The photo shows there are no bolts in the three visible locations, while the fourth is covered with insulation.

The preliminary NTSB report with photographic proof of missing bolts….has so much interest its crashed the NTSB website. pic.twitter.com/dAgUhNeoNy

— Paul Breed (@unrocket) February 6, 2024

“The investigation continues to determine what manufacturing documents were used to authorize the opening and closing of the left MED plug during the rivet rework,” the NTSB said in the report.

The NTSB added that after the plane left the Boeing factory to the time of the accident it “found no evidence that the left plug was opened after leaving Boeing’s facility”.

Boeing response to report

Following the report being published Boeing President and CEO Dave Calhoun said: “Whatever final conclusions are reached, Boeing is accountable for what happened. An event like this must not happen on an airplane that leaves our factory. We simply must do better for our customers and their passengers.”

He added: “We are implementing a comprehensive plan to strengthen quality and the confidence of our stakeholders. It will take significant, demonstrated action and transparency at every turn – and that is where we are squarely focused.”

Boeing announced it had implemented a control plan to ensure all 737-9 mid-exit door plugs are installed according to specifications.

This included new inspections of the door plug assembly and similar structures at Boeing’s supplier’s factory and on its own production line.

The company said it had also added “signage and protocol to fully document when the door plug is opened or removed in our factory, ensuring it is reinstalled and inspected prior to delivery”.