Jetstar Airways A320 takeoff incident in 2020 was caused by a forgotten screwdriver tip, left in the Airbus jet engine, Australian investigators reveal in a report.

Jetstar Airways Airbus A320 jet flight crew had to abort the takeoff due to engine power loss and low speed back in October 2020. In a final report released on August 16, 2021, the Australian Transport Safety Bureau (ATSB) confirmed the initial conclusions of a crucial human factor error.

Suspicious engine vibrations and a “popping noise” on takeoff

On October 23, 2020, Jetstar Airways Airbus A320-232 aircraft, registered as VH-VFF, was supposed to operate a regular flight between Brisbane (BNE) and Cairns (CNS), Queensland, Australia. There were 165 passengers and six crew members on board.

Shortly after the push-back, the first officer taxied the aircraft for takeoff on the dedicated runway 01L. Once the flight crew received approval for a takeoff, they lined up the plane and set a particular engine thrust level, which was counted based on the VH-VFF weight, flap settings, and the runway length available at the time.

However, as soon as both engines spooled up to the needed power, pilots noticed an unusual vibration which was followed by a “popping noise” in which volume was continuously increasing. In the meantime, the plane instantly deviated to the right of the runway centreline. To stop the diverged aircraft, the first officer pressed the left-hand rudder pedal in full but the move did not help, so the captain selected reverse thrust and the jet decreased the speed to 30 knots. When the thrust levels returned to idle, the suspicious vibration and sound stopped.

Meanwhile, the Electronic Centralised Aircraft Monitoring (ECAM) system, which monitors and displays information over the engine and aircraft system malfunctions, displayed two error messages of engine No.2, alerting the flight crew about “STALL” and “EGT [Exhaust Gas Temperature, -ed.] LIMIT EXCEEDANCE”.

Following the alarm, the captain notified the cabin crew about the emergency, telling them to prepare for evacuation. In the meantime, passengers informed the cabin crew about flames coming from the right-hand engine. But since neither the airport rescue nor firefighting teams observed any obvious abnormalities with the aircraft, the captain taxied the jet to the airport gate and shut both engines down.

A human factor leads to significant mechanical damage

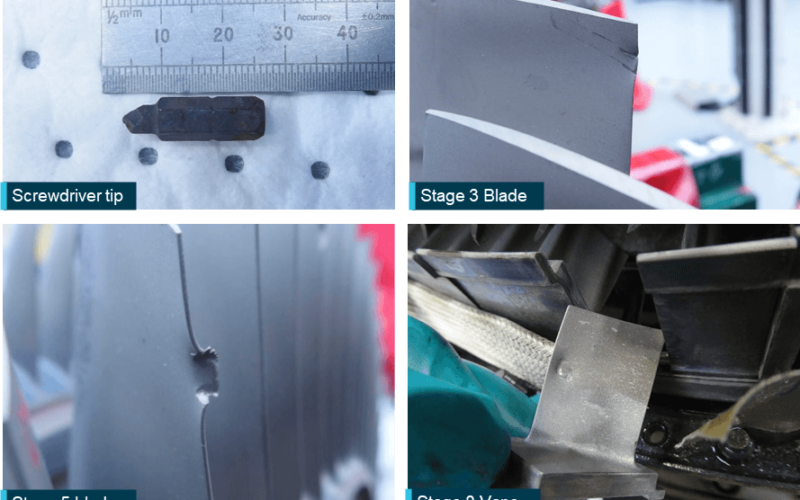

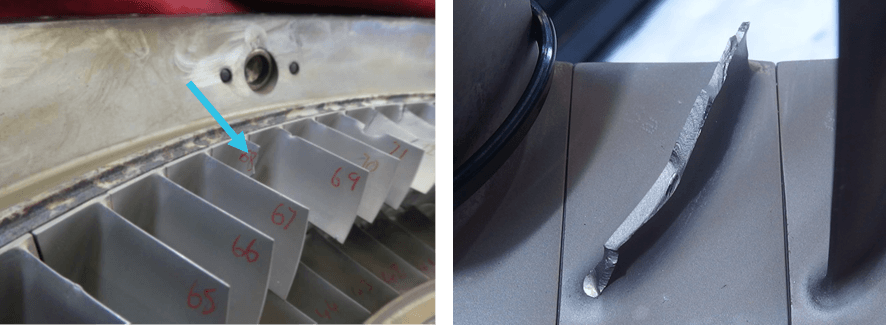

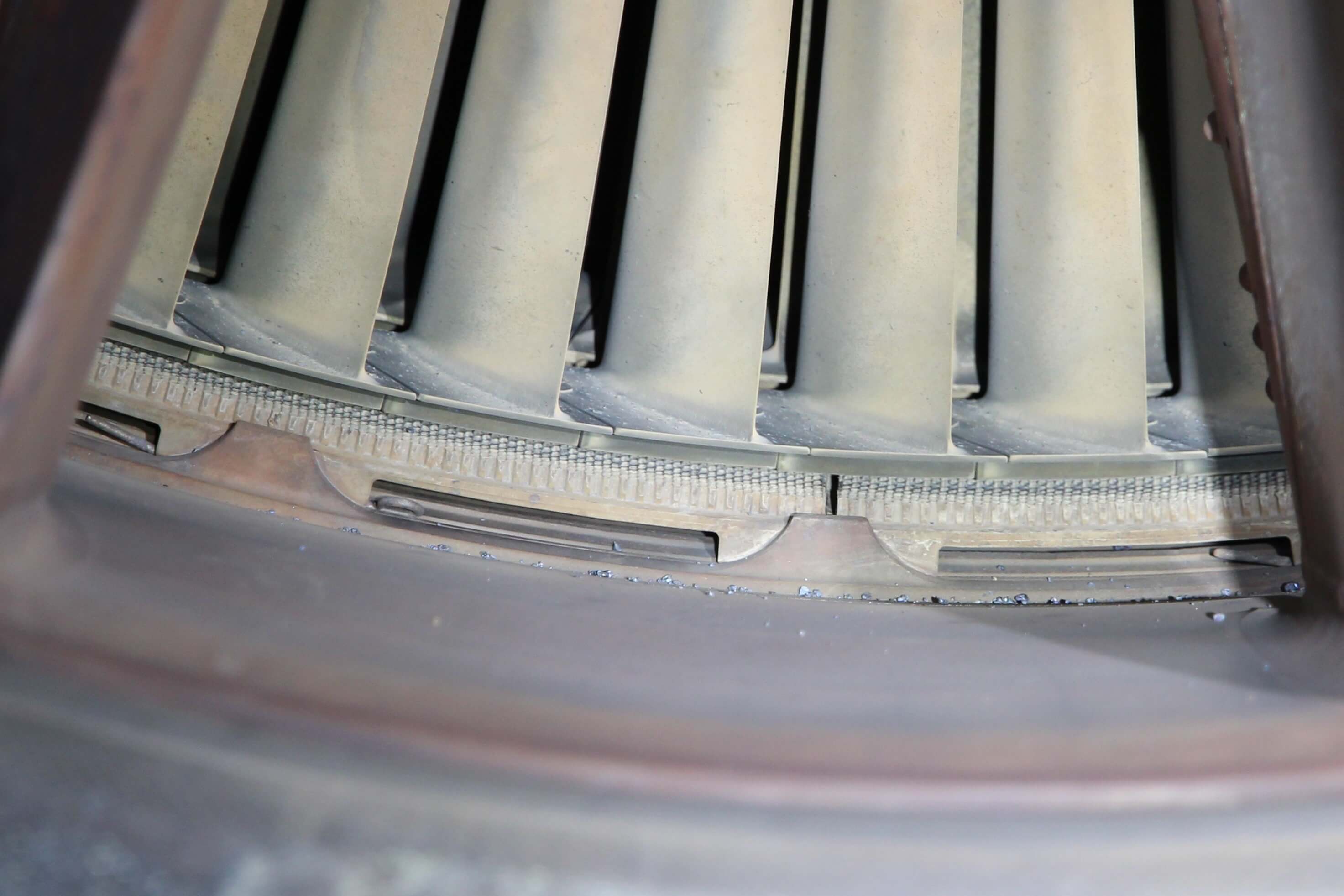

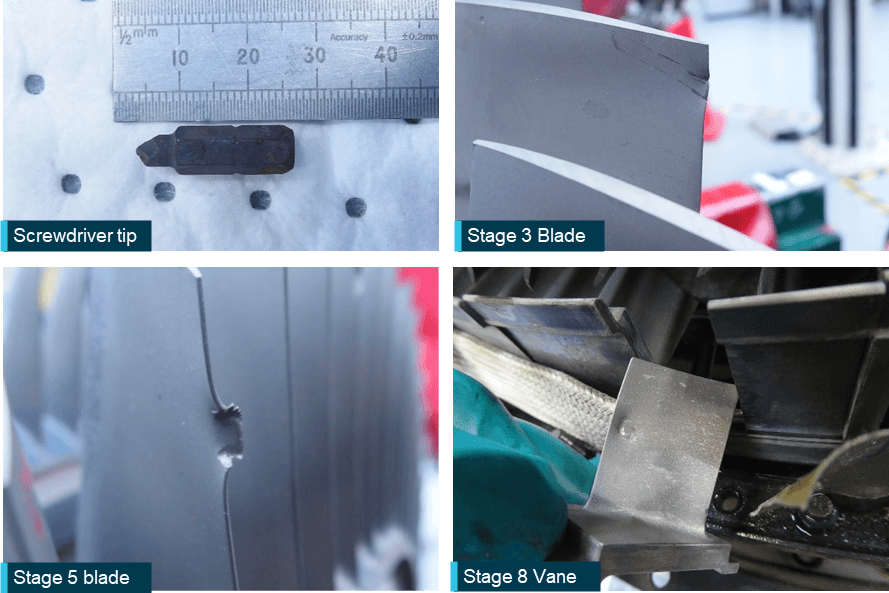

As soon as all 165 passengers disembarked the plane, engineers inspected the plane and found small balls of metallic debris in the tailpipe of the right-hand engine. According to the report, as the damage was outside maintenance manual limits, the right-hand jet engine was removed and sent for a teardown inspection, where engineers found a screwdriver tip in the high-pressure compressor (HPC) combustion section, which had caused the HPC damage. In addition to the HPC damage, some of the rotor blades and stators had also been minorly affected.

Jetstar Airways, annotated by the ATSB

Small metallic debris and a screwdriver tip were found between the combustion liner and engine case. The screwdriver tip was burnt and the tip eroded “due to heat and mechanical damage”, as written in the report. Many engine components throughout the HPC matched the shape of the screwdriver, meaning that the item must have been in the engine for more than 100 flights.

Jetstar Airways, annotated by the ATSB

The ATSB found that the tool bit had been left in the engine during regular maintenance, when the engine was removed to lubricate the LPC Bleed Valve Mechanism.

“The ATSB concluded the tool bit had been left in the engine after maintenance and when the engine was running, it entered the high-pressure compressor, leaving dents and nicks in numerous rotor blades and stator vanes,” the ATSB Director Transport Safety Stuart Macleod was quoted in the report explaining.

ATSB

Jetstar Airways response to the matter

The tool control is considered a crucial part of aircraft maintenance processes that ensure they do not lead to any object damage, the ATSB highlighted. Jetstar Airways conducted a risk assessment and issued a safety alert to their maintenance engineers, outlining the importance for all tooling to be accounted for.

Jetstar Airways