The advanced air mobility sector is far from lacking in projects and entrepreneurs all aiming to change how we get around. However, some of these ventures appear to be ahead of the pack.

One of those early pioneers is Lilium, a Germany-based startup, which, almost a decade after it was founded in 2015, is approaching the last key stages before launching its electrically powered vertical takeoff and landing (eVTOL) aircraft.

This sleek, futuristic-looking aircraft, called the Lilium Jet, will be able to carry five people (four passengers and a pilot) over distances of up to 175 kilometers (about 108.74 miles).

This type of range is essential for Lilium’s primary mission, which is to enable regional air mobility. An approach that has set the German company apart from other eVTOL developers which have focused on urban mobility instead.

AeroTime visited Lilium’s headquarters located on the outskirts of Munich, Germany, to find out more about the company intent on upending the air mobility industry.

“The vision of the company is to be the leader in the regional air mobility segment,” explained Sebastien Borel, Lilium’s Chief Commercial Officer (CCO).

“We want to connect cities with each other,” Borel continued. “That’s the most important aspect of our business because even the architecture of our aircraft is meant to address the regional mobility connecting cities with each other. When you fly longer distances, you create more time savings, and you also remove a lot more CO2 on the ground.”

This is a segment of the market that has attracted the interest of a number of electric aviation entrepreneurs, although many of those targeting regional air mobility have opted for conventional takeoff and landing designs, which are said to involve fewer development risks.

But Borel made the case for eVTOL vehicles like Lilium’s to tackle the need for regional air mobility, instead, noting that an advantage of eVTOL technology is it allows you to land closer to the point of interest.

“If you want to create time savings, you want to be closer to the city and to be closer to the city you need to take off and land vertically,” he said.

Borel added that Lilium is looking at many different cities as potential markets for the Lilium Jet. These locations offer space and infrastructure that could potentially serve as vertiports for Lilium operations close to city centers.

First, Lilium intends to target the private and business aviation sector.

“If you look at the number of flights that are made on a yearly basis by jets, private jets, or helicopters, well guess what? If you’re looking at flights under 230 kilometers, we can address 20% of all of the business aviation flights in the world. That’s massive,” Borel said, before adding that the Lilium Jet aircraft has several additional benefits over traditional aircraft. These advantages include the absence of carbon emissions and improved safety through a distributed propulsion architecture and 30 electric motors, which provide redundancy.

However, the German firm is also keeping an eye on the mass market.

Not only does Lilium envisage its aircraft creating a new market for air mobility connecting cities at a regional level, but it is also looking at ways for airlines to integrate eVTOL operations with their mainline businesses. This is why it has partnered with airlines like Lufthansa and Saudia.

While traffic volumes may be potentially small in absolute numbers, the capacity to offer flexible and efficient air mobility services could provide those airlines able to offer this type of service with an edge in the premium segment of the market, where they make most of their profits.

Borel was also optimistic about technological advances, particularly in batteries, which should also help expand the aircraft range in years to come. Battery technology is an area that is essential enough for Lilium that it has opted to internalize parts of its production.

Lilium works with a couple of partners to develop battery cells, namely using the promising silicon technology, and has started to produce battery packs in-house.

“The needs [when it comes to battery technology] are very specific to the aviation industry,” Borel said. “So, using an off-the-shelf battery would not make sense, given the requirements that we have from the regulator.”

Lilium is also working with a partner to develop the whole charging solution, including the charging stations and the cables.

However, pilotless flights are not currently on the cards for Lilium.

When talking about the possibility, Borel referred to his previous role as a senior Airbus executive where projects to evaluate potential reductions in cockpit crew numbers never went ahead, even if technically feasible, in great part because of a mix of regulatory and public acceptance issues.

Nevertheless, the need to have a pilot onboard and associated staff costs do not prevent eVTOLs from being competitive in operational costs, according to Borel.

“The industry has been discussing two euros per seat kilometer and I strongly believe that we’d be able to go below this and probably more towards 1.5 euros per city kilometer,” he stated confidently.

So, how much will it cost to buy a Lilium Jet?

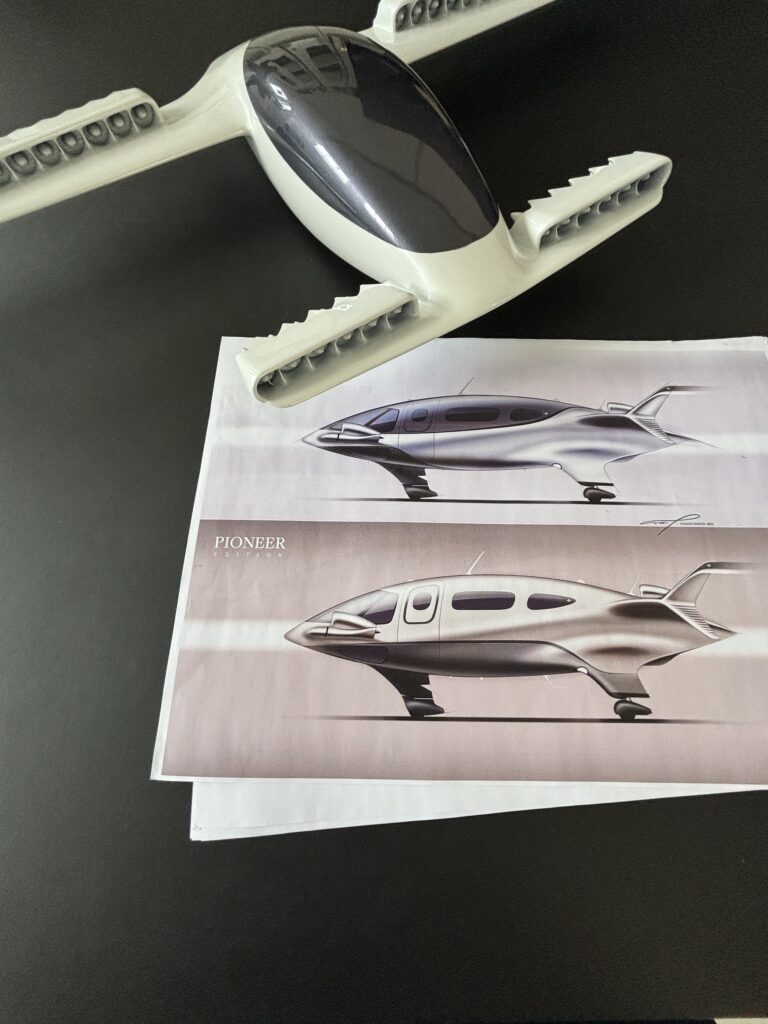

Much like many other markets, it will depend on how many you are willing to order. It will be somewhere in the US$7 to 10 million range, depending on whether you are a fleet operator with a standard configuration or wish to order just one unit of Lilium’s special “Pioneer Edition” aircraft, which will feature a specially designed cabin interior.

Borel explained that Lilium is working with several financial entities that currently cannot be named in order to offer a range of financing options. These are likely to be announced soon.

However, the elephant in the room was, of course, the high technological and financial risks that technologically disruptive projects like the Lilium Jet entail. This is something that the markets are painfully aware of.

Lilium’s share price has taken a beating since listing on the NASDAQ in September 2021 after merging with a Special Purpose Acquisition Company (SPAC). The company has raised additional funds on several occasions during the last 12 months to expand its runway until it can start generating cash.

All of this happens amid general concerns that the eVTOL sector may be short of funds. In April 2024, for example, another German eVTOL pioneer Volocopter, raised alarms after it was denied funding in the form of government-backed loans.

However, Borel appeared confident about Lilium’s financial perspectives and highlighted how, after a decade-long maturation process, the German company is preparing for the final sprint towards aircraft certification and entry into service.

“We are always working on making sure that we have what is needed to get to the finish line In an 18 month timeframe, we raised approximately 400 million US-Dollar, I feel very confident given where we are. You’ve seen the aircraft, it’s moving forward. We’re moving into production.”

Visiting Lilium’s HQ in Germany

Our visit to Lilium’s headquarters also allowed us the chance to peek behind the scenes and see how the Lilium Jet is, quite literally, taking shape ahead of its expected entry into service in 2026.

Lilium’s campus extends over several facilities at the edge of the Oberpfaffenhofen airfield, in the southwest of the Bavarian capital, where its offices, design and production facilities are located.

Flight testing with prototypes is being conducted at another facility located in Jaén province, in southern Spain, where space is abundant and test crews can enjoy clear skies pretty much year-round.

As part of AeroTime’s tour of the facility, we were given the chance to check out two full-scale mockups of earlier iterations of the Lilium Jet. These had already been on display at aviation events throughout 2023, such as EBACE and the Paris Air Show.

Several modifications have since been introduced into the final production version of the aircraft, such as the reduction in the number of electric motors, from 36 to 30.

An adjacent building houses something that is yet to make its public debut – the first Lilium Jet production aircraft, MSN01.

There, in the workshop (at this stage the production process is still pretty much an artisanal process), stood the half-finished airframe, still devoid of the outer finishings, propulsion units and avionics, offering us a glimpse at the future of air mobility as it is being made.

Our visit was completed with a tour of the design studio, where the Lilium Jet’s distinctive drop-shaped lines were conceived. It is also where full-scale mockups are made using materials that allow the designers to physically proof every single detail of the customer experience before going to final production design.

Last but not least was a visit to Lilium’s simulator center that offered this correspondent a hands-on way to experience the Lilium Jet and gain a realistic feel of what the upcoming eVTOL revolution could bring us.